Hot-rolled stainless steel strips are made from hot-rolled stainless steel strips after further hot rolling. Compared with cold-rolled strip, it has higher dimensional accuracy, lower surface roughness, better surface quality, smoothness and higher strength. Therefore, a thinner hot-rolled strip can be used instead of a thicker cold-rolled strip for the same purpose to save the amount of steel, which is of great economic significance.

Hot-rolled stainless steel strip can be divided into five types according to the structure characteristics: austenite type, austenite-ferrite type, ferrite type, martensitic type and precipitation hardening type, which can be selected when used.

The difference between rolled strips

① Hot rolling

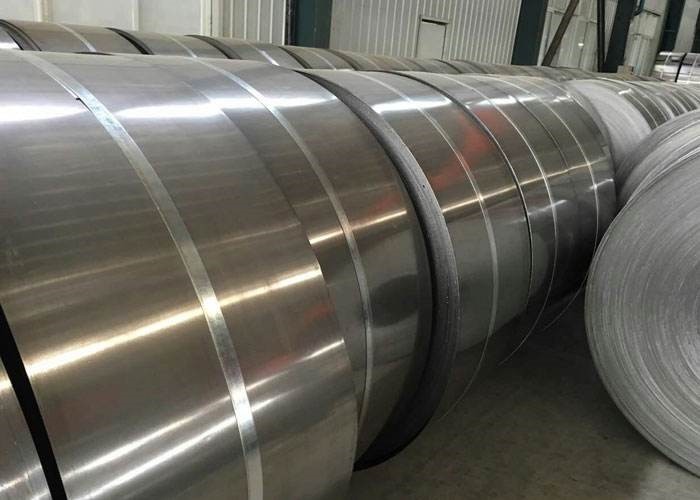

Using slab (mainly continuous casting slab) as raw material, after heating, it is made into strip steel by rough rolling unit and finishing rolling unit. The hot steel strip coming out of the last rolling mill of finishing rolling is cooled to the set temperature by laminar flow, and then rolled into a steel strip coil by the coiler. The cooled steel strip coil undergoes different finishing operations according to the different needs of users. Lines (leveling, straightening, cross-cutting or slitting, inspection, weighing, packaging and marking, etc.) are processed into steel sheets, flat rolls and slitting steel strip products. To put it simply, after a piece of billet is heated (that is, the kind of red hot steel block that is burned), it is refined and rolled several times, and then trimmed and corrected into a steel plate. This is called hot rolling.

② Cold rolling

Using hot-rolled steel coil as raw material, after pickling to remove oxide scale, cold continuous rolling is carried out, and the finished product is rolled hard coil. The cold work hardening caused by continuous cold deformation increases the strength, hardness and toughness and plastic index of rolled hard coil. , so the stamping performance will deteriorate and can only be used for parts with simple deformation. Hard-rolled coils can be used as raw materials for hot-dip galvanizing plants, because hot-dip galvanizing units are equipped with annealing lines. The weight of the rolled hard coil is generally 6~13.5 tons, and the hot-rolled pickled coil is continuously rolled at room temperature. The inner diameter is 610mm.

Product features: Because it has not been annealed, its hardness is very high (HRB is greater than 90), and its machinability is extremely poor. Only simple directional bending of less than 90 degrees (perpendicular to the coiling direction) can be performed.

In simple terms, cold rolling is processed and rolled on the basis of hot rolled coils. Generally speaking, it is a processing process such as hot rolling-pickling-cold rolling.

Cold rolling is processed from hot-rolled sheets at room temperature. Although the temperature of the steel sheet will be heated up during the processing, it is still called cold rolling. Due to the continuous cold deformation of hot rolling, the mechanical properties are relatively poor and the hardness is too high. It must be annealed to restore its mechanical properties, and those without annealing are called hard rolled coils. Hard-rolled coils are generally used to make products that do not need to be bent or stretched, and are bent on both sides or four sides with a thickness of 1.0 or less.