Classification of patterned aluminum plate

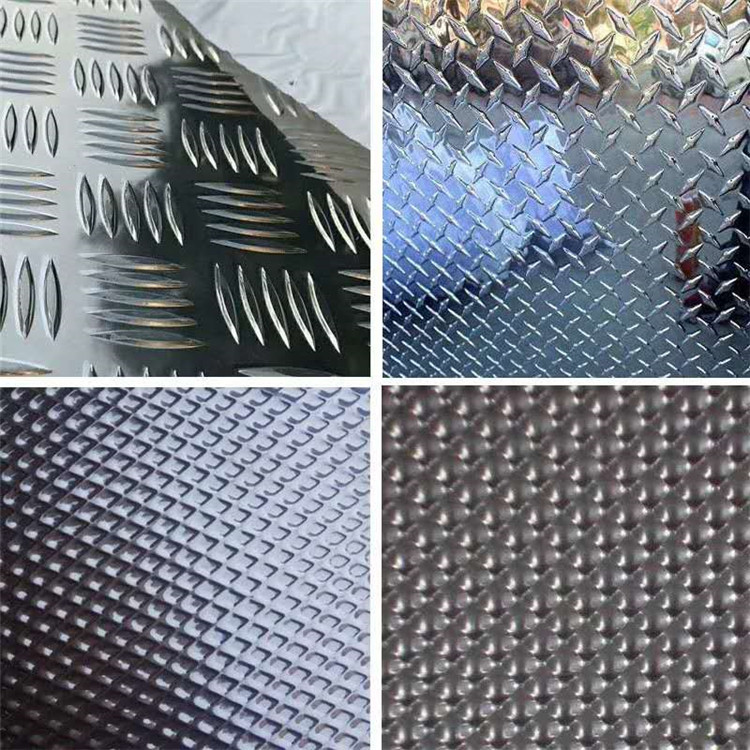

1. Five-rib pattern aluminum plate: This kind of plate is also called willow-shaped pattern plate, which has good anti-skid performance and is widely used in the construction industry.

2. Pointer pattern aluminum plate: This kind of plate is called anti-skid aluminum plate, and its performance is similar to that of five ribs, but this material plate is not commonly used.

3. Lentil pattern aluminum plate: a kind of plate that is not commonly used, not only has a good anti-slip effect, but also the price is affordable. Commonly used in carriages.

4. Spherical pattern aluminum sheet: The surface of this sheet presents a small spherical pattern, which is also widely used in life.

5. Ordinary patterned aluminum plate: With 1060 aluminum plate as the base material, the aluminum alloy patterned plate is suitable for any environment, with affordable price and good function.

6. Aluminum alloy pattern aluminum plate: with 3003 as the main raw material, this kind of aluminum plate is also called anti-rust aluminum plate, its strength is higher than that of ordinary aluminum alloy pattern plate, and its anti-rust performance is better.

7. Aluminum-magnesium alloy pattern aluminum plate: It is processed with 5 series aluminum plates such as 5052 or 5083 as raw materials. This material aluminum plate has good corrosion resistance, high hardness and good rust resistance.

The patterned aluminum plates that mainly play a non-slip effect include five-rib patterned aluminum plates and pointer-type patterned aluminum plates. It is mainly used for anti-skid on the ground or working platform. At present, the pedal is widely used, and it is widely used in the anti-skid of the carriage and the bottom of the ship warehouse.

5052 pattern aluminum plate is a representative product of anti-skid aluminum plate. The advantages of this series of products are: high hardness, this series belongs to the representative series of alloy aluminum plate, and has high tensile strength, and the hardness has obvious advantages in similar products (similar products) Aluminum-magnesium alloy products also include 5754 pattern aluminum plate). It has strong corrosion resistance and good rust prevention effect. This series of products are added with magnesium alloy in the processing process, and the content can reach more than 2.5%. It has good corrosion resistance and rust resistance, and can be well adapted to high strength and high resistance. In corrosive occasions, it has a good application effect on ships, vehicles and work platforms, and has great advantages compared to 1060 pattern aluminum plates.

What problems should be paid attention to in the fire protection of patterned aluminum panels?

External wall insulation should organically combine the four disciplines of construction science, material science, fire protection science and environmental protection science. Any research that deviates from the four disciplines is relatively one-sided and limited. To do a good job in the fire prevention of patterned aluminum panels, you need to pay attention to a few aspect. Hardening the aluminum plate means that the aluminum plate is cold deformed below the recrystallization temperature, such as casting, calendering, drawing, stretching, etc. During cold deformation, the dislocation density inside the aluminum plate increases, and entangles with each other and forms a cellular structure, preventing dislocations. wrong movement. The greater the degree of deformation, the more severe the dislocation entanglement, the greater the deformation resistance and the higher the strength. The degree of strengthening after cold deformation varies with the degree of deformation, deformation temperature and the properties of the material itself. When the same material is cold deformed at the same temperature, the greater the degree of deformation, the higher the strength and the lower the plasticity.

1. Strictly implement various fire regulations and fire guidelines.

2. Choose a good thermal insulation material.

3. Take fire prevention measures in the initial stage of the use of patterned aluminum panels.

4. In the intermediate stage of the use of patterned aluminum plates, pull the aluminum plates for the monitoring requirements of the construction process to prevent various fires.

5. After making the thermal insulation system for the patterned aluminum plate, use it correctly and prevent the occurrence of fire.

Adding certain alloying elements to pure aluminum to form an infinite solid solution or a limited solid solution can not only obtain high strength, but also obtain excellent plasticity and excellent press working function. The most commonly used alloying elements for solid solution strengthening in aluminum sheets are copper, magnesium, manganese, zinc, silicon, nickel and other elements. Usually, the alloying of aluminum plates constitutes a limited solid solution, such as Al-Cu, A-Mg, Al-Zn, Al-Si, A-Mn and other binary alloys constitute a limited solid solution, and all have a large limit solubility to increase Larger solid solution strengthening effect.