Hot-dip galvanized steel strip is a high-performance, high-value-added product produced by hot-rolled coils as raw materials through the method of cold rolling-annealing-galvanizing. Hot-dip galvanized products can reduce corrosion and extend the life and save energy on steel Material saving plays an immeasurable and irreplaceable role, and is currently widely used in the automotive and home appliance industries.

Chromatic aberration defects are a general term for defects on the surface of galvanized steel strips, which directly affect the appearance and coating effect of galvanized steel strips, and more seriously, they can also have negative effects on the mechanical properties of the strips.

From an optical point of view, the chromatic aberration defect is caused by the abnormal surface roughness of the defect location, which results in a difference in the reflectivity of the defect area to the light. According to the analysis of the current research status at home and abroad, the main factors related to strip chromatic aberration defects are: uneven surface roughness of the strip, foreign matter on the surface of the zinc layer, and uneven grain size of the zinc layer.

Edge chromatic aberration

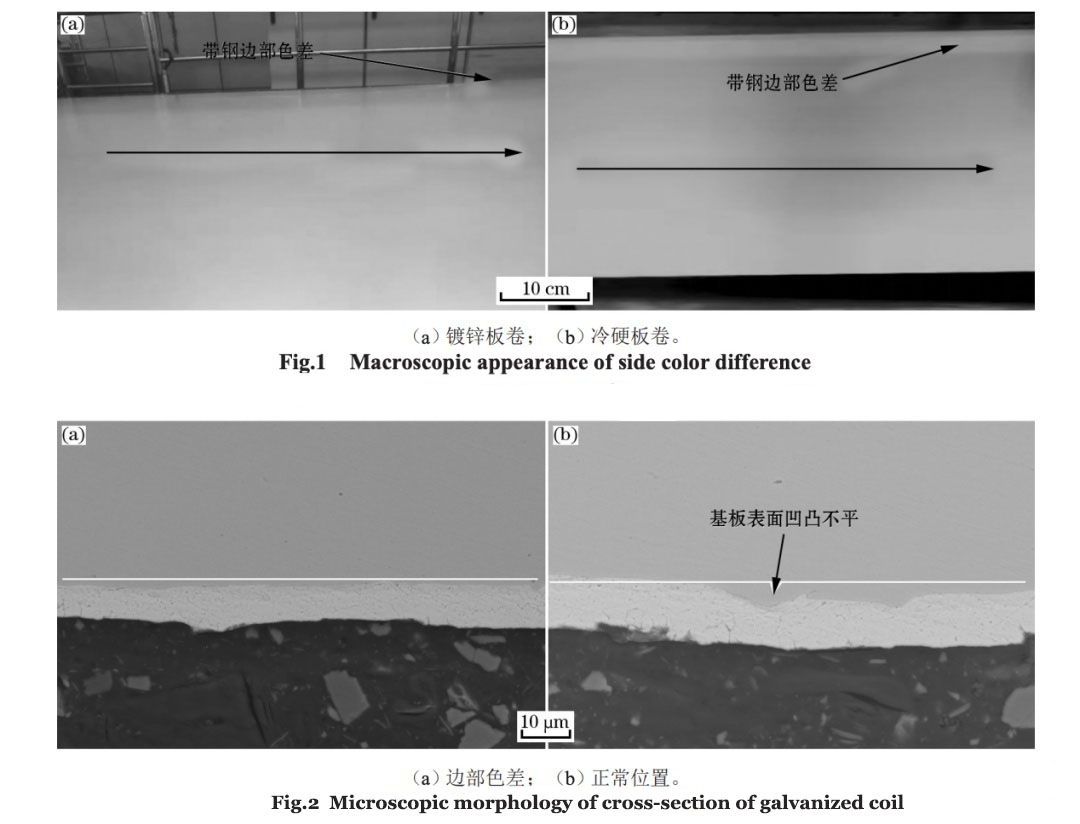

The macroscopic appearance of the edge chromatic aberration defect is shown in the figure. Figure (a) The chromatic aberration of the edge of the galvanized sheet is about 5cm from the edge of the steel strip. The entire roll is continuous, and it is slightly brighter than the normal surface position. Detected with a hand-held roughness meter, the edge chromatic aberration position roughness Ra is 0.56μm, and the normal board surface position roughness Ra is 0.72μm.

Figure (b) The chromatic aberration of the curled edge of the chilled plate is also located at about 5cm from the edge of the strip, and the whole roll is continuous, which is slightly whitish compared to the normal surface position. Due to the thick surface of the hot-rolled coil, chromatic aberration defects cannot be observed with the naked eye. Due to the chromatic aberration of the edge, the defect position of the raw material coil and the finished coil is relatively strong, and the chromatic aberration of the galvanized sheet edge is suspected to be caused by the raw material.

Subsequently, samples were taken of the galvanized finished coils and the same batch of raw material coils with edge color differences to observe the microscopic morphology of the surface and cross-section. Figure 2 shows the chromatic aberration position and the normal position of the galvanized curling edge under the electron microscope. It can be seen that in Figure 2(a), the edge color difference position, the surface of the galvanized substrate is relatively flat, and the thickness of the zinc layer is about 7-10μm; The layer thickness is about 10-12 μm.

The thickness of the zinc layer at the chromatic aberration part of the galvanized sheet is thinner and the roughness is lower. This is due to the low roughness of the galvanized raw material chilled coil within 5 cm from the edge. In the cooling process of the hot rolling process, the edge of the strip has a faster cooling rate, resulting in fine grains, higher hardness and strength, and a thin and dense oxide scale at the edge of the strip.

After the hot-rolled coil with such characteristics is pickled, the dense iron scale on the edges is easy to remain. After cold tandem rolling, the edge roughness of the chilled coil is lower due to the strengthening of the edge grain and the lubricating effect of the oxide scale.

Based on this, formulate corresponding improvement measures. In the actual production process of hot rolled coils, the control of the uniformity of the transverse temperature is mainly through adjusting the water distribution of the upper header to form a convex water flow distribution. In order to control the chromatic aberration defects at the edge of the galvanized product, the edge shielding method is adopted on the cooling device, and different shielding strategies are adopted according to different strip widths, thicknesses, and steel grades, which improves the transverse direction during the cooling process of hot rolled coils. The unevenness of temperature, organization, and stress distribution.

Color difference after polishing

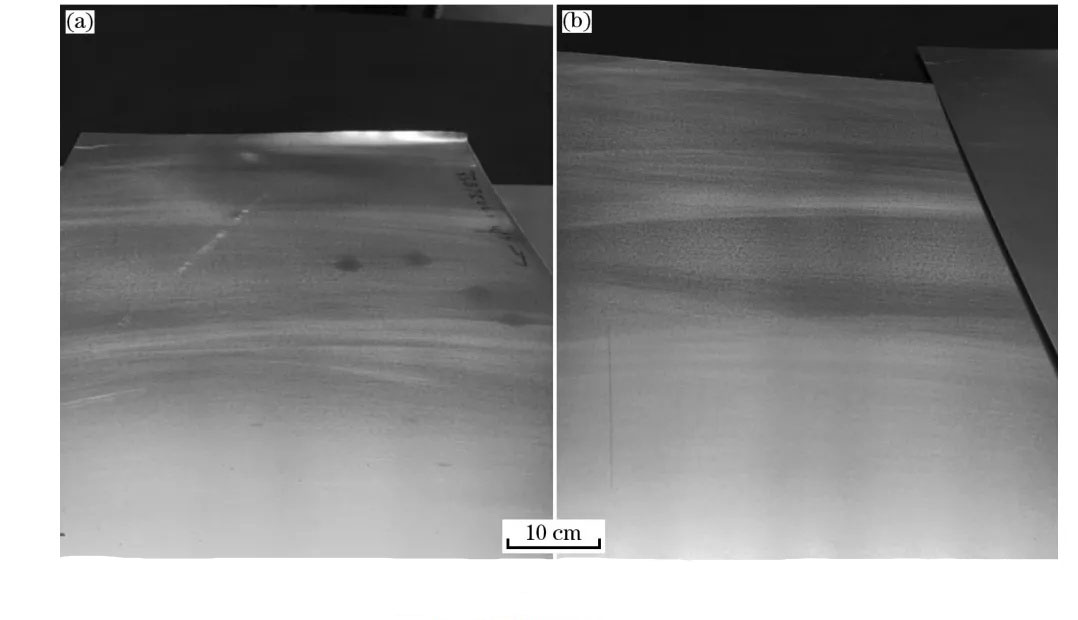

The macro morphology of the chromatic aberration defect after grinding on the surface of the hot-dip galvanized steel strip is shown in Figure (a), which is a dark black circle; the macro morphology of the sand disk at the position without chromatic aberration is shown in Figure (b).

The strip steel at various positions behind the zinc pot was polished, and there were defects in the color difference after polishing, indicating that the defect occurred at the position of the air knife of the zinc pot.

Under the same air knife process parameters, observe the strip jitter situation: when the strip running speed is 60m/min, the strip runs smoothly, basically without jitter, the surface is basically the same after polishing, and the color difference defect is not obvious; when the strip running speed When it is 100m/min, there is slight swaying of the strip steel, and the surface chromatic aberration defects are obvious after grinding.

This shows that the color difference after polishing has a greater correlation with the operating speed of the production line, and the jitter amplitude after the strip steel is drawn from the zinc pot. The strip steel will change the distance between the upper and lower air knives during the shaking of the strip. Under the same air pressure, the change of the air knife distance will cause the thickness of the zinc layer to change.

The main reasons for the jitter after the strip zinc tapping pot are: (1) The installation accuracy of the sinking roller is poor, or the shaft sleeve of the sinking roller is seriously worn after the use of the sink; (2) The incoming version is poor; (3) The cooling section is fast after plating. The spray pressure on the upper and lower surfaces of the cold air box is inconsistent.

For the hot-dip galvanizing process, the following measures are formulated to control the strip jitter: (1) After the sinking roll is processed and before installation, check its surface roughness and grooves for chamfering, burrs and burrs, and whether it will affect the installation accuracy. When installing the sinking roller, check whether the centerline of the steel strip between the inking roller and the top roller of the cooling tower is consistent; (2) Adjust the air volume on the upper and lower surfaces of the moving wind box in the cooling section after plating, so that the baffle openings of the upper and lower surface wind boxes are The pressure is consistent.

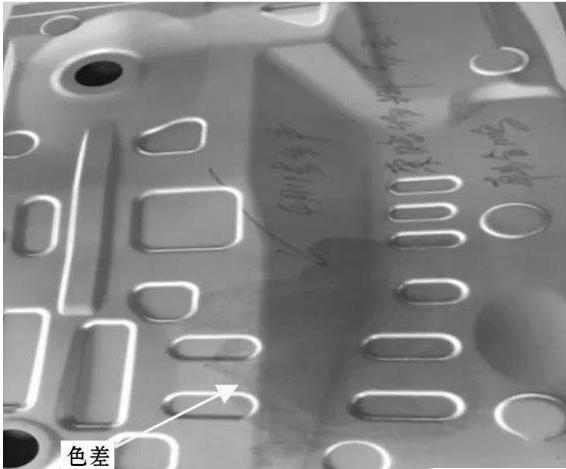

Color difference after stamping

After stamping, the chromatic aberration defect appears on the stamping part of the hot-dip galvanized steel sheet.

The chromatic aberration defect after stamping is caused by the destruction of the zinc layer on the surface of the galvanized steel sheet during the stamping process, causing internal oxidation of the zinc layer, resulting in chromatic aberration defects on the surface of the stamping part. There are many factors influencing the surface damage of galvanized steel sheet stamping, such as steel sheet galvanizing process, mold material, lubrication effect and so on.

Prevent surface damage through measures such as surface strengthening and lubrication of the stamping die. The main measures are: (1) Nitriding treatment on the surface of the stamping die; (2) The effect of different lubricants has been studied through tensile extrusion tests. The research shows that the surface film formed by the lubricant on the surface of the friction pair can reduce the stamping part Surface damage.

Conclusion

1. The chromatic aberration at the edge of the galvanized sheet is caused by the low roughness of the cold rolled galvanized material within 5cm from the edge. In the cooling process of the hot rolling process, the edge of the strip has a fast cooling rate, fine grains, high hardness and strength, and a thin and dense iron oxide scale.

After pickling, the dense iron scale on the edges remains. In the cold tandem rolling process, the edge roughness of the chilled coil is low due to the strengthening of the edge grain and the lubrication of the oxide scale. In order to control the chromatic aberration defect at the edge of the galvanized product, the edge shielding method on the cooling device is used to improve the unevenness of the transverse temperature, structure, and stress distribution during the cooling process of the hot rolled coil, so that the chilled coil and the galvanized The overall surface quality of the roll has been significantly improved.

2. The chromatic aberration defect of the galvanized steel strip surface after sanding the disc is relatively related to the operating speed of the production line and the jitter amplitude after the strip steel is drawn from the galvanized pot. During the shaking process of the strip steel, the distance between the upper and lower air knives of the strip will be changed. Under the same air pressure, the change of the air knife distance will cause the thickness of the zinc layer to change. Therefore, it is necessary to control the vibration of the strip, improve the installation accuracy of the sinking roller, and adjust the air volume on the upper and lower surfaces of the moving wind box in the cooling section after plating, so that the baffle opening and pressure of the upper and lower surface wind boxes are consistent.

3. The chromatic aberration defects appear on the stamping parts of the hot-dip galvanized steel sheet after stamping, because the zinc layer on the surface of the galvanized steel sheet is damaged during the stamping process, cracks appear, and the zinc layer appears internally oxidized, resulting in chromatic aberration defects on the surface of the stamping parts. Therefore, it is necessary to perform nitriding treatment on the surface of the stamping die; add lubricant during the stamping process, and the surface film formed by the lubricant on the surface of the friction pair can reduce the surface damage of the stamping part.