Formation mechanism of hot-dip galvanized coating

Hot-dip galvanizing is a metallurgical reaction process. From a microscopic point of view, the hot-dip galvanizing process is two dynamic balances: heat balance and zinc-iron exchange balance. When the iron and steel workpiece is immersed in the molten zinc solution at about 450°C, the workpiece at normal temperature absorbs the heat of the zinc solution, and when it reaches above 200°C, the interaction between zinc and iron becomes obvious gradually, and zinc penetrates into the surface of the iron workpiece.

As the temperature of the workpiece gradually approaches the temperature of the zinc solution, alloy layers containing different zinc-iron ratios are formed on the surface of the workpiece, forming a layered structure of the zinc coating. As time goes on, different alloy layers in the coating show different growth rates. From a macro point of view, the above process is manifested as the workpiece is immersed in the zinc liquid, and the zinc liquid surface boils. When the zinc-iron reaction is gradually balanced, the zinc liquid surface gradually calms down. The workpiece is raised from the zinc liquid surface, and when the temperature of the workpiece gradually drops below 200°C, the zinc-iron reaction stops, and a hot-dip galvanized coating is formed with a certain thickness.

Hot-dip galvanized coating thickness requirements

The main factors affecting the thickness of the zinc coating are: the composition of the base metal, the surface roughness of the steel, the content and distribution of the active elements silicon and phosphorus in the steel, the internal stress of the steel, the geometric size of the workpiece, and the hot-dip galvanizing process.

The current international and Chinese hot-dip galvanizing standards are divided into sections according to the thickness of the steel. The average thickness and local thickness of the zinc coating should reach the corresponding thickness to determine the anti-corrosion performance of the zinc coating. For workpieces with different steel thicknesses, the time required to achieve thermal equilibrium and zinc-iron exchange equilibrium is different, and the thickness of the formed coating is also different. The average thickness of the coating in the standard is based on the industrial production experience value of the above-mentioned galvanizing mechanism, and the local thickness is the empirical value required to consider the unevenness of the thickness distribution of the zinc coating and the requirements for the corrosion resistance of the coating.

Therefore, the ISO standard, the American ASTM standard, the Japanese JIS standard and the Chinese standard have slightly different requirements on the thickness of the zinc coating, which are similar. Next, we will explain several different hot-dip galvanizing and coating characteristics.

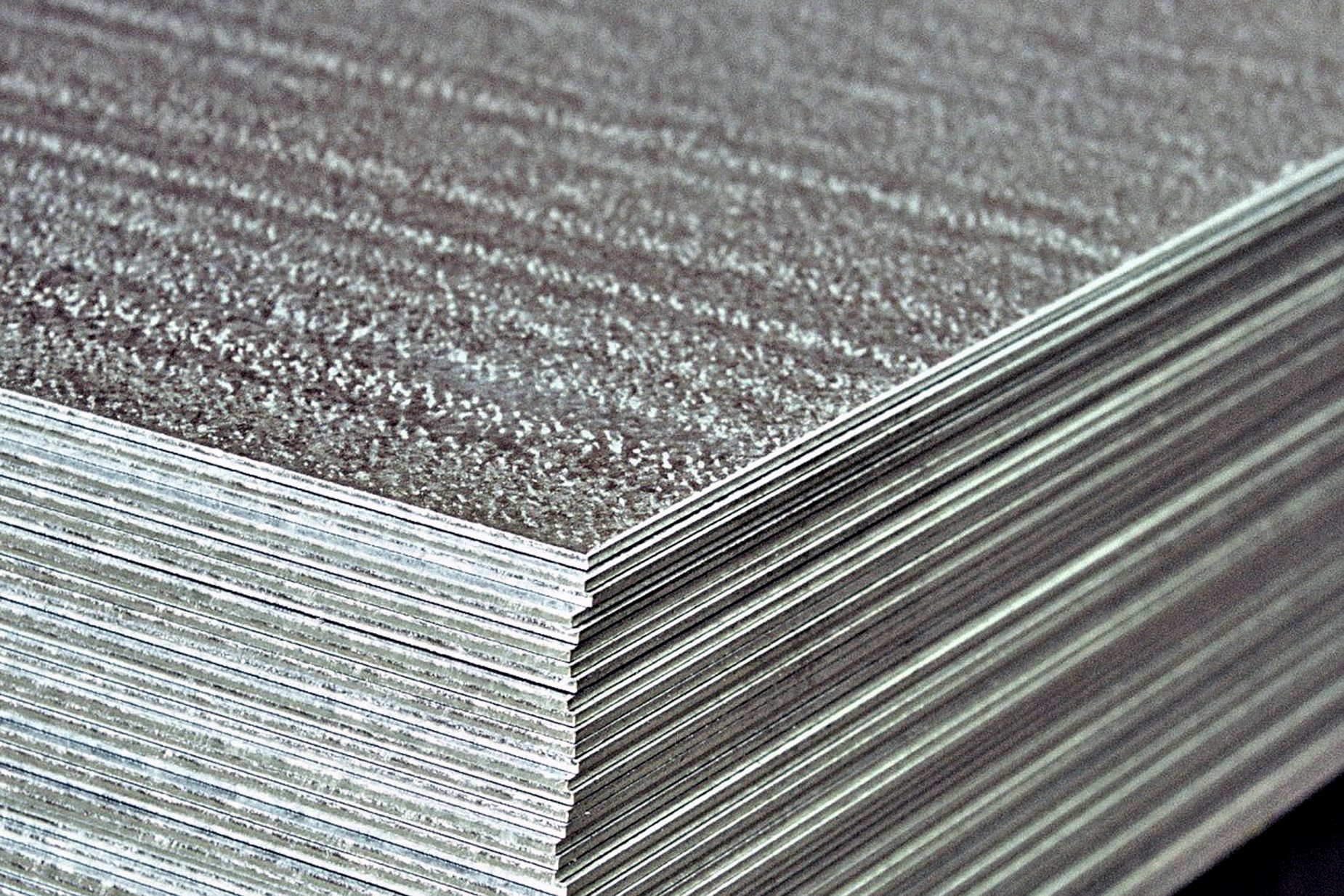

1. Hot-dip galvanized steel plate (GI plate)

At present, 0.2% Al element is added to the zinc liquid used in the production of GI boards. The role of adding AI is to improve the fluidity of the zinc solution. Aluminum and iron elements react preferentially to form an iron-aluminum alloy phase layer, which inhibits the reaction between zinc and the steel plate substrate, thereby improving the coating adhesion. At the same time, a small amount of aluminum in the zinc solution is added to the zinc Aluminum oxide film is formed on the surface of the liquid, which prevents the oxidation reaction of zinc on the surface of the zinc liquid and reduces zinc consumption. On the surface of the coating, aluminum can first react with oxygen to form a layer of aluminum oxide protective film, which prevents the oxidation of the coating surface and increases the surface brightness.

GI plate is a typical cathodic protection mechanism that uses sacrificial anode (zinc) to protect the steel substrate from corrosion, and GI plate is the most common and widely used coated steel plate, in various industries such as construction, home appliances, automobiles, transportation, agriculture, etc. Lots of applications.

The surface of the GI plate coating is composed of platforms and uniform pits. The formation of the morphology is mainly due to the skinning roll with a certain roughness after galvanizing, so that the surface of the coating forms a surface with a roughness of about 1 μm. The GI plate is composed of the outermost pure zinc layer, the steel substrate and the middle layer of a thin inhibitory layer, that is, the iron-aluminum alloy phase layer FeAl3 or Fe2Al5 phase. The iron-aluminum alloy phase prevents the diffusion of iron to the zinc layer and prevents the coating from forming relative The brittle zinc-iron alloy phase ensures the adhesion of the coating.

2. Hot-dip galvanized alloy coated steel plate (GA plate)

The GA plate is a coated steel plate that is heat-treated at 500-550°C after galvanizing to allow the iron and zinc in the steel matrix to diffuse each other to form a zinc-iron alloy phase layer. The iron content on the surface of the coating is about 10% (mass fraction).

The GA plate needs to be heat treated after galvanizing to make the zinc and iron interdiffused, thereby forming a zinc-iron alloy phase. Therefore, in order to reduce the alloying time and reduce the barrier effect of the inhibition layer, the Al content in the zinc solution will be higher than that in the GI plate zinc solution. It should be low, generally around 0.13%. The iron element in the coating improves the overall corrosion potential and weldability of the coating, but the formation of the zinc-iron alloy phase layer increases the brittleness of the coating, and the coating is prone to pulverization or peeling during the deformation process, which affects the service life of the molding die.

The formation process of the zinc-iron alloy phase layer increases the surface roughness of the coating, reduces the color, and makes the surface of the coating gray and dark. Greater roughness increases the coatability of the coating. At the same time, the coating surface with greater hardness and surface roughness has better sand and stone impact resistance. Therefore, GA board has better corrosion resistance, welding performance, coating performance and sandstone impact resistance than GI board, but its formability is relatively poor, and it is not as bright as GI board.

GA boards are used as automotive panels, mainly for Japanese and Korean cars. The production of GA boards has strict requirements on the production control of the zinc-iron alloy coating layer, so the process control requirements are relatively high, and domestic production has been mature.

The surface of the GA plate coating is composed of rough zinc-iron alloy phase δ1p and a small amount of ξ phase. The outermost layer is relatively loose columnar crystal δ1p and a denser δ1k layer close to the substrate. There is about 1 μm thick Г at the junction of the coating and the substrate. Layers.

3. Hot-dip galvanized steel plate (GL plate)

Hot-dip galvanized coatings generally include Galfan (GF) coatings containing 5% Al and Galvalume (GL coatings) containing 55% Al. At present, hot-dip aluminum-zinc coatings for continuous strips generally refer to 55.0% Al and 43.4% Zn coatings. , 1.6% Si Galvalume steel plate is GL plate.

Due to the high aluminum content in the GL plate coating, the coating has the corrosion resistance and high temperature oxidation resistance of aluminum, and the presence of zinc makes the coating have cathodic protection performance. At present, GL boards are generally used as color-coated boards in construction, automobiles, home appliances, agriculture and other industries. At the same time, they are directly used in mufflers, exhaust pipes, refrigerator back panels, electronic microwave ovens, heat exchangers, etc.

The diameter of spangles on the surface of GL coatings is generally 1-3mm. Since there are many factors affecting the size of spangles, the coating spangles will also vary in a wide range with the content of alloying elements in the zinc bath or the cooling rate after plating. , Generally speaking, the spangle size is also allowed in a larger range of 0.2-5.0mm.

The GL coating is composed of two layers, the outer layer is an aluminum-zinc alloy layer, which is composed of a dendritic aluminum-rich solid solution and a zinc-rich phase between dendrites. The inner layer is an Al-Zn-Fe intermetallic compound layer, which is located between the Al-Zn alloy layer and the steel substrate. It is similar to the GI coating structure. The inner Al-Zn-Fe intermetallic compound layer of the GL coating prevents iron elements from entering the Al-Zn alloy. layer, increasing the adhesion of the coating, while the addition of silicon limits the growth of the brittle Al-Zn-Fe intermetallic compound layer.

4. Hot-dip galvanized aluminum-magnesium coated steel plate (ZnAlMg plate)

ZnAlMg plate originated in Japan. Due to the maritime climate of the island country and many typhoons and earthquakes, high strength and high corrosion resistance of steel are required. At the same time, Japan’s resources are scarce and the supply and demand of production raw materials are tight. Therefore, ZnAlMg plate was developed to improve corrosion resistance and be effective. Use resources to reduce costs and protect the environment.

Due to the different components of aluminum and magnesium in ZnAlMg plates developed by different companies, there have been many ZnAlMg plates with different composition ratios. For example, Nisshin Steel developed ZAM (Zn-6%Al-3%Mg) products, Nippon Steel’s SuperDyma plate (Zn-11%Al-3%Mg) products, Thyssen’s ZnMgEcoprotect (Zn-1%Al-1%Mg) products, VAI’s Corrender (Zn-2%Al-2%Mg) products, ArcelorMittal's Magnelis (Zn- 3.7%Al-3.0%Mg) products, etc.

The ZAM plate coating is composed of the outer layer and the alloy layer at the junction of the outer layer and the substrate. The outer layer of the coating is composed of an aluminum-rich phase and a Zn/Al/Zn2Mg ternary eutectic phase. The corrosion resistance of the ZnAlMg coating is greatly improved compared with that of the GI coating. For example, the corrosion resistance of the ZAM plate coating can even reach 16 times of the corrosion resistance of the GI coating.

In the ZnAlMg coating, the key role in improving the corrosion resistance is that Mg2Zn11 or MgZn2 is distributed in the crystal boundary and dendrite gap, which has good edge corrosion resistance and good processability, and is suitable for building materials. Due to the high hardness of the outer surface, it can also resist the surface wear during the forming process, which is beneficial to be used as an environmentally friendly and resource-saving coated steel product.