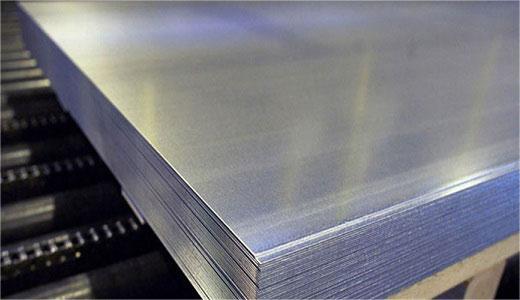

430 stainless steel is a ferritic straight chromium non-hardenable stainless grade with good corrosion resistance and formability as well as useful mechanical properties. Its resistance to nitric acid allows it to be used in specific chemical applications, but automotive trim and appliance parts are its largest areas of application.

430F stainless steel is a free machining version of this grade that can be used for bars on automatic screw machines. Grade 434 is a molybdenum bearing version of Grade 430 with the same combination of properties. Its molybdenum addition improves corrosion resistance.

These properties of 430 are specified in ASTM A240/A240M for flat rolled products (sheet, plate and coil). Other products, such as forgings and bars, specify similar but not necessarily identical properties in their respective specifications. ASTM A582 specifies the properties of Class 430F.

Typical applications for 430 stainless steel include: dishwasher liners, refrigerator cabinet panels, automotive trim, lashing wires, fasteners, and more.

Grade 430 has good resistance to a variety of corrosive environments, including nitric acid and some organic acids. It achieves maximum corrosion resistance in highly polished or ground conditions. Generally speaking, its resistance to pitting corrosion and crevice corrosion is close to 304 grade. The stress corrosion cracking resistance of grade 430 is very high as it is suitable for all ferritic grades.

Like other high-sulfur free-machining grades, 430F has greatly reduced resistance to pitting and crevice corrosion compared to non-free-machining grades.

Grade 430 is resistant to interstitial oxidation up to 870°C and continuous use up to 815°C. This grade may become brittle at room temperature after prolonged heating in the 400-600°C range. This effect can be eliminated by annealing.

In terms of heat treatment, solution annealing, heating to 815-845°C, holding for half an hour per 25mm thickness, slow cooling in the furnace to 600°C, followed by rapid cooling. Slow cooling from 540-400°C will result in embrittlement. Subcritical annealing is heated to 760-815°C, and then air-cooled or water-quenched. This grade cannot be hardened by heat treatment.

If welding is required, preheat 430 stainless steel to 150-200°C. Embrittlement of the weld metal and heat affected zone can be alleviated by post-weld annealing at 790-815°C.

This stainless steel is easier to machine than the standard austenitic grade 304. There is still a trend of wear and tear on cutting tools. Lightly drawn rods are easier to machine than rods in the annealed condition. Grade 430F, the free machining version of the 430, is very easy to machine.

In product manufacturing, the lower work hardening rate makes bending and forming a bit easier than grade 304, and the lower ductility limits very strict operations. Severe bending should be performed when the bending axis is at right angles to the rolling direction. Severe cold heading of 430 wire is possible.